Targeting ideal injectivity and flowback capabilities of a porous gas storage reservoir.

Improvement In Marginal Field Economics

Reduction In Total Well Construction Cost

Savings in Workover Costs

Sustained Increase in Gas Production

Transformative Technology, Deep Technical Expertise

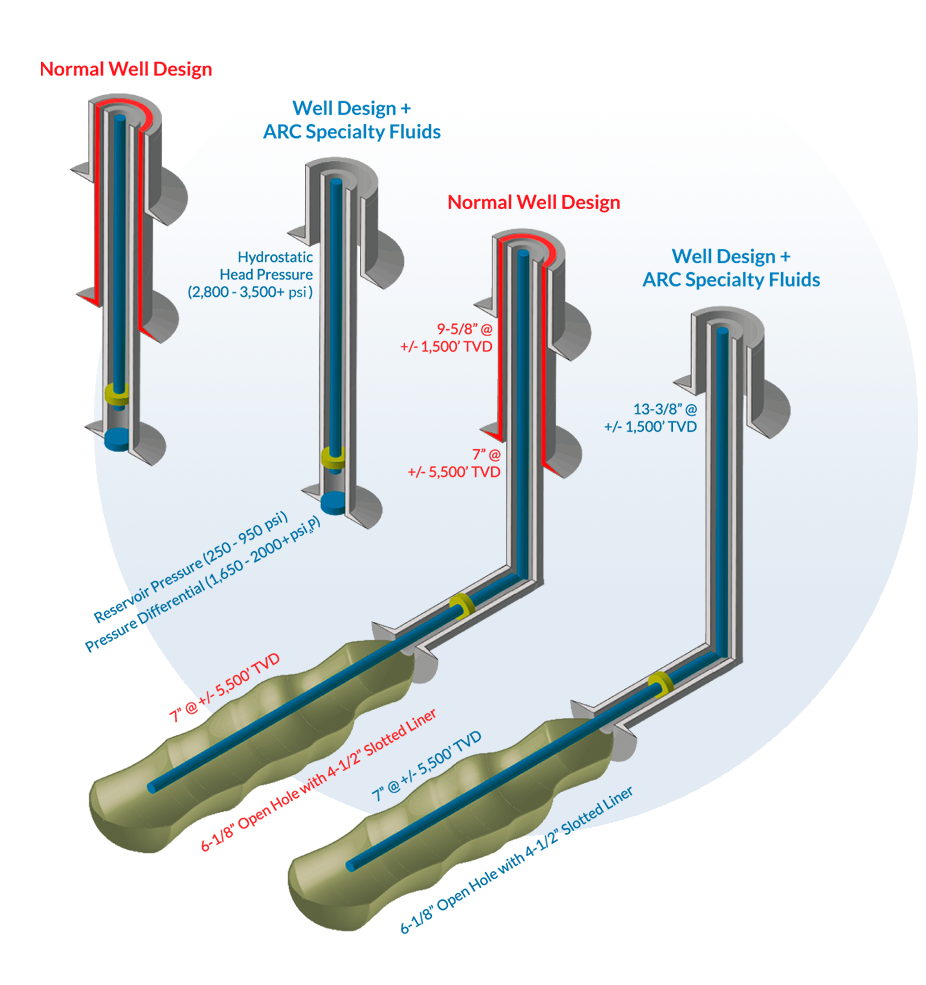

We have helped operators reduce their well design by one hole size and eliminates a casing string in areas where severe depletion exists.

We would be pleased to visit with you for the purpose of determining whether or not this engineered and proven solution is viable for consideration on your project.

Proper care of porous gas storage media is being responsible to your bottom line. Drill, complete and workover to maximize your reservoir potential.

We are happy to visit with you about achieving this economic performance goal.

Our engineered solution is designed specifically to complement the drilling operations and improve economic control.

These services are proven, environmentally safe and cost-effective.

Ingenious inventiveness, mastered and transformative

Overcoming operational and economic hurdles of today’s unconventional wells requires new thinking and technology. Dimensional analysis of the challenges, realistic goal identification, and careful execution with proven technologies drastically improves your project economics.

Total Storage Control

Well Construction

Zero Skin

Total Circ Control

ARC Master Fluids

Flow Hackers

Liquid Pipe

Zone Guard

Explore Our Services

Project Planning

When building a program to fit your application, we will work with your team to design a fluid package offering that will take into consideration: Goal achievement , Cost, Reservoir protection, Well bore integrity, Drilling efficiencies, Drilling equipment compatibilities, HSE and Environmental impact.

Complimentary Checks

Our engineering management provides oversight on all ARC field activities and engineers throughout the entirety of the program, ensuring everything is executed properly. You can count on direct support and expert problem-solving from beginning to end.

On-site Support

In addition to ARC management oversight we provide full wellsite lab testing equipment and a drilling fluids engineer on location to ensure “around the clock” supervision of the program throughout the project.

Zone-specific Support

Additional on-location support (2nd engineer) is available for specific well interval(s) posing potential high risk drilling challenges.

Insights

Here you will find news items, product updates and information, white papers, case studies, and more!

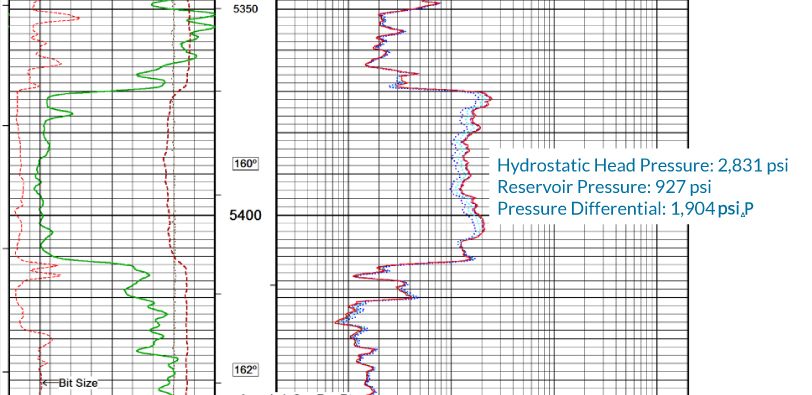

This case history provides an implementation overview of the drilling fluid services in 2014 on the East Cheyenne Gas Storage project (now owned by Enstor Inc.). The intent of this document is to provide a discussion, system design and benefits overview of what occurred on the wells.

Check out CEO, Tony Rea's, SPE paper on optimizing reservoir permeability to hydrocarbons with micro-solution technologies.

Discover our paper presented at the ONGC International Drilling Fluids conference in Mumbai, India.